Electric Motors Inspection

- May 13, 2021

- 1 min read

Updated: Mar 15, 2023

When motors malfunction due to attrition or overheating, they will compromise the performance of the entire production line. Thermal imaging cameras can be used to efficiently and reliably inspect motor malfunctions.

Customer’s Challenge

Electrical motors play an important role in the automation production line, the heart of the modern mechanical manufacturing industry. The motors in automation lines usually operate 24/7.

When motors malfunction due to attrition or overheating, they will compromise the performance of the entire production line. And, according to maintenance data statistics, an electric motor's lifetime will be reduced by half, and its surface temperature raised by 10 °C.

While traditional maintenance methods such as vibration analysis or thermal probing are either inefficient or unreliable.

The Solution

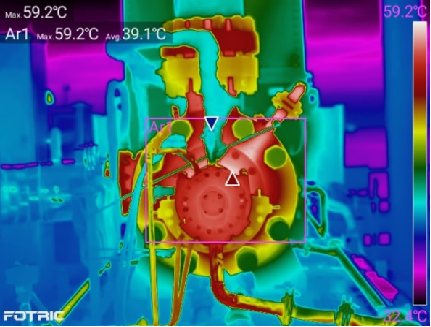

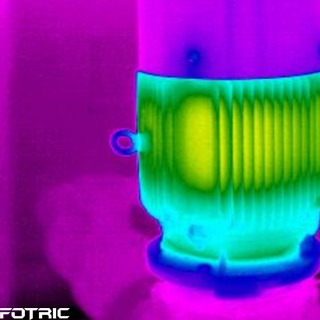

Thermal imaging cameras can be used to efficiently and reliably inspect motor malfunctions. Most issues of a motor system, including lubrication issues, misalignments, overload, aging, mechanical damage, attrition, overheating, and circuit shortcuts, will manifest themselves in the form of temperature abnormality.

Advanced handheld thermal cameras FOTRIC 348A/346A/326M with 40 mK of sensitivity, can not only measure surface temperature accurately but also record historic thermal distribution image data, to perform trend analysis, therefore determining if and when the system requires maintenance or replacement.

The Result

Firstly, by using FOTRIC non-contact thermal inspection method, engineers do not need to stop production during maintenance, and can quickly get analysis results in one shot.

Normally, after those faults are detected, engineers will use more professional test tools for deeper diagnosis.

With more efficient and reliable periodic maintenance, the factory automation line’s production rate will highly improve, therefore bringing more financial returns to users.