Electric Substation Inspection

- May 13, 2021

- 2 min read

Updated: Mar 10, 2023

Infrared thermal imaging has been used to ensure the stable and safe operation of the power supply. Fotric 348-L25 provides an intuitive analysis interface for maintenance engineers, making the predictive maintenance of electric substations more efficient and safe.

Customer's Challenge

As a non-contact inspection method, infrared thermal imaging has been used in China's electric power grid company since the early 1980s, to ensure the stable and safe operation of the power supply.

In recent years, due to the country's electric consumption high-speed growth, the requirement for predictive maintenance has grown increasingly higher. For example, the demand for the frequent site diagnosis of voltage heating defects in substations has become stronger, and this kind of application is demanding in imaging quality and accuracy.

Fotric 348-L25 is an advanced handheld thermal imager, with 640x480 resolution and 40 mK sensitivity, and a 5-inch 1280x760 LCD screen, which provides an intuitive analysis interface for maintenance engineers.

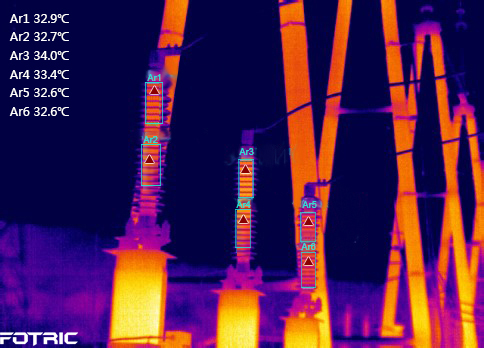

Solution 1: 110KV Bus Lightning Arrester

From the bus lightning arrester’s thermal images on 348A’s screen, the temperature overview distribution shows voltage heating defects, uneven temperature rises from bottom to top. So, although the elevated temperature is only 1.4K, according to the national standards of IR imaging diagnosis, it appears critically defective, which indicates that this component must be replaced immediately.

Solution 2: Voltage Transformer’s 35KV bushings

From the high-voltage bushing’s thermal images on the 348A screen, the temperature overview distribution shows voltage heating defects and overall heating. So an elevated 3.4K temperature is also a critical defect, according to the national standards of infrared imaging diagnosis, which means that this component must be replaced immediately.

Result

Equipped with FOTRIC 348A with a 25° lens, our clients can run predictive maintenance of electric substations more efficiently and more safely. Not only does it save the inspection service’s working hours, but also prevents production shutdown, which could threaten the power supply of residence communities or industrial factories. In addition, it also makes the electric substation operation safer by reducing potential fire accidents caused by abnormal temperature rises.